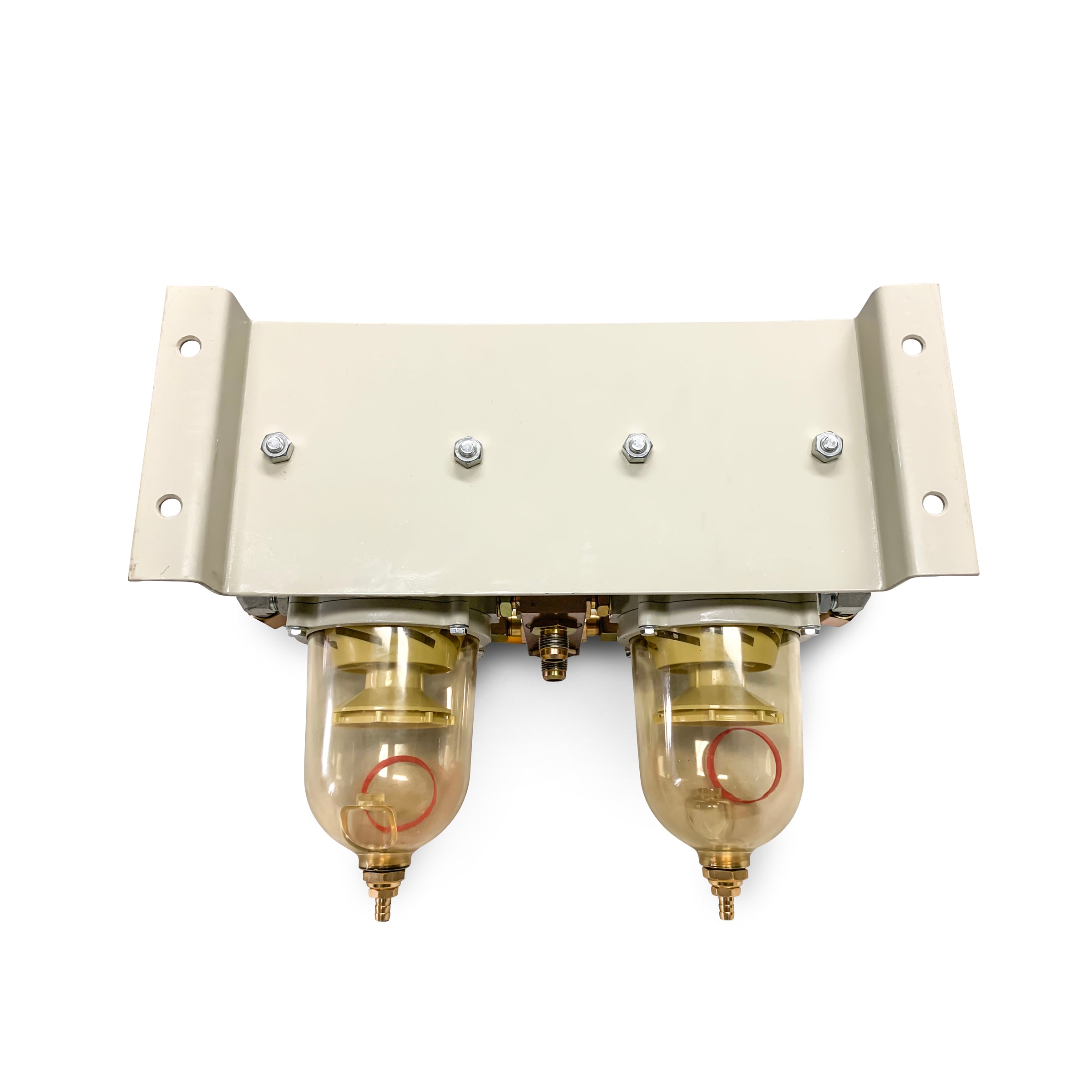

Fuel Filter Water Separator Duplex.

Description

A duplex turbine water separating filter offering protection for the largest equipment in your fleet.

Based on our single Turbine Fuel Filter now comes a duplex style filter joined to a manifold. With a twin primary filter setup, and a manual change-over valve. These filters make use of reusable bowls on the bottom, that feature water bleed-off valves. With the duplex setup you can achieve a maximum flow rate up to 1,368 l/h diesel supply to your engines.

Diesel Fuel Filter & Water Separator Duplex Unit

Stage 1 - Separation: As fuel enters the filter assembly, it moves through the centrifuge and spins off large solids and water droplets which fall to the bottom of the collection bowl.

Stage 2 - Coalescing: Small water droplets bead-up on the surface of the conical baffle and cartridge element. When heavy enough, they too fall to the bottom of the bowl.

Stage 3 - Filtration: Water rejecting cartridge elements repel water and remove contaminants from fuel down to two microns (nominal). They are waterproof and effective longer then water absorbing elements.

The Duplex Turbine filter takes 900FH elements, SM for 2 Micron, TM for 10 Micron & PM for 30 Micron.

Why a Duplex Diesel Filter Water Separator?

- Engines will benefit from a 99% water separation, no better vanguard protection for your engine saving you tens of thousands of dollars in repair and servicing costs down the track.

- The duplex design allows for 1 element to be isolated and replaced without impacting the fuel flow through the other element.

- Removes water that enters the system via condensation in the fuel tank. Any water present in the fuel stream will support bacterial growth, which can cause clogged filters and result in the formation of corrosive acids. Susceptible components then rust and corrode, leading to erosion and wear of critical fuel system components.

- Removes common fuel contaminants such as silica and sand particles.

Dirty Diesel Fuel

In some parts of the world, 10,000 gallons of "typical" diesel contains 1-1/2 lbs (700grams) of hard particulate; this is 1000 times more than the 1/4 oz. (0.7 grams) per 10,000 gallons that are allowed by the cleanliness requirements of high-pressure common rail fuel systems.

Dirty fuel will cause premature parts failure in equipment of any age. New diesel fuel systems aka High-Pressure Common Rail Fuel (HPCR) are standard on most diesel engines today. Which means dirty diesel's negative impact is more pronounced in newer systems due to the extreme high pressures.

Dirty fuel causes performance issues in your diesel engine and allows for rust and corrosion to initiate costly damage..

What Causes Dirty Fuel

If your diesel engine is starting to feel sluggish, it's likely your injectors are starting to become clogged which will then lead to reduced fuel efficiency. So what causes this? In summary, contaminants. Even the transfer of the fuel from pipelines introduces contaminants as most are not new. Contaminants come from barges, rail cars, terminal tanks, storage tanks and the common fuel bowser. The new fuel is already contaminated when it pumps into your tank. Contaminants can also come from your own fuel tank and your own fuel system itself. Wear particles are created by mechanical friction. High heat and extreme pressure generated inside the modern engine, lead to coking and the creation of carbon products at the injectors. Much of this internally produced particulate is returned to the fuel tank via your return diesel line.

Hence the need for as much protection as you can possibly muster, we supply our duplex version of the 1000FH for extra front guard protection.

Features and Benefits:

- Heavy duty construction

- Installs quickly with mounting plate provided

- Quality manifold block to direct and isolate flow

- Perfect for duty/standby filter designs

- Easy to service without shutting down engine

- Clear collection bowl allows for water identification

- Self-venting water drain

- Includes fittings to suit common 10mm / 3/8" fuel hose

The filter bowl includes a density sensitive flag which floats on water but sinks in diesel. This helps the operator to quickly see if water is present in the bowl and needs to be drained.

Cross-Referenced Filters:

- DONALDSON P552040

- RACOR 900FH

| Specification | 900FH/Duplex |

|---|---|

| Flow Rate (LPH) | 1368 |

| Height (mm) | 559 |

| Width (mm) | 152 |

| Depth (mm) | 178 |

| Element removal clearance | 254 |

| Max. Pressure (PSI) | 15 |

| Bowl Capacity (mL) | 305 |

| Clean Pressure Drop (PSI) | 0.43 |

| Water Removal Efficiency | 99% |

| Max. Fuel Temperature | 88° C |